Agitated Glass Nutsche Filter – Premium Filtration System for Efficient Solid-Liquid Separation

Introducing our Agitated Nutsche Filter, the ideal solution for efficient solid-liquid separation in various industries. Engineered with precision, our filter combines the benefits of agitation and filtration to ensure optimal performance in laboratory and industrial applications.

Key Features

- Closed System for Maximum Purity: The Agitated Glass Nutsche Filter is a closed vessel system that facilitates solid-liquid separation by filtration under vacuum. This setup ensures that your processes are contamination-free, odorless, and maintain product integrity.

- High-Quality Glass Construction: Made from durable borosilicate glass, our Nutsche Filter offers excellent chemical resistance, ensuring long-lasting use in diverse environments.

Efficient Filtration: The unique design promotes rapid filtration and thorough washing of solids, minimizing product loss and enhancing yield.

Agitation Mechanism: The built-in agitation system ensures uniform mixing and facilitates better filtration, making it ideal for challenging separation tasks.

Versatile Applications: Perfect for pharmaceuticals, chemicals, and food industries, our filter can handle a wide range of materials and processes.

| Cat. Ref. | Working Vol (ltr) | Filter area (m2) | Vessel Dia | Vessel height | Motor Capacity HP |

|---|---|---|---|---|---|

| ANF10 | 10 | 0.03 | 225 | 300 | 0.5 |

| ANF20 | 20 | 0.06 | 360 | 325 | 0.5 |

| ANF50 | 50 | 0.12 | 400 | 450 | 0.5 |

| ANF200 | 200 | 0.31 | 600 | 775 | 1 |

| ANF300 | 300 | 0.31 | 600 | 1150 | 1 |

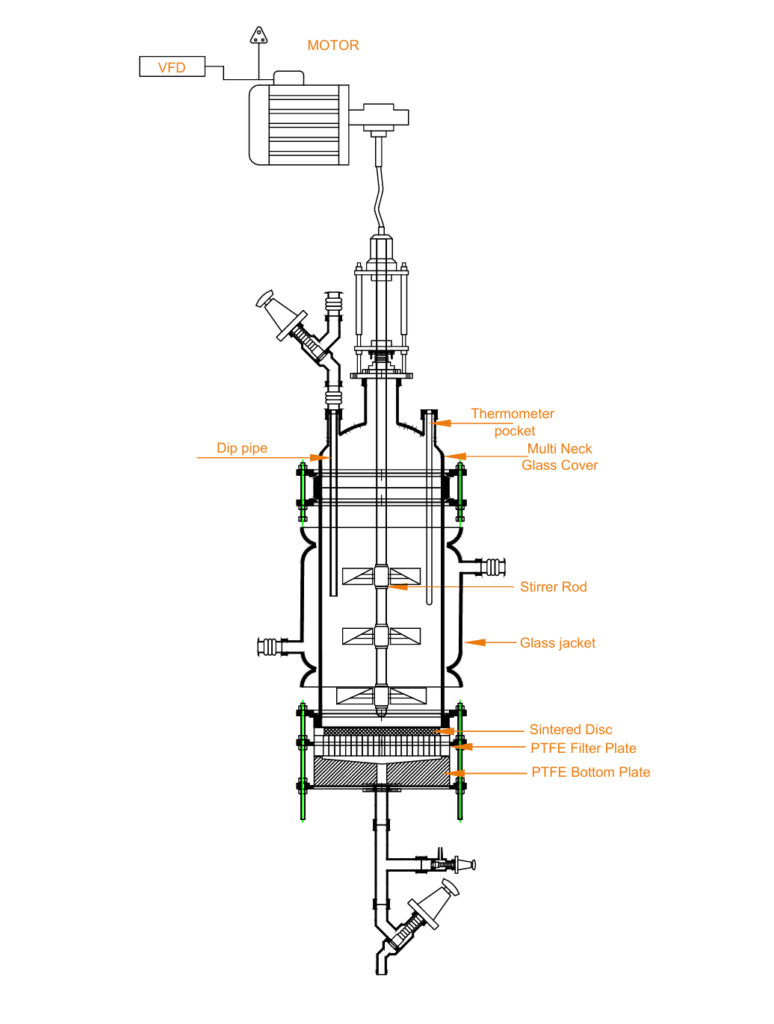

Components of the Agitated Glass Nutsche Filter

- Drive Assembly: Equipped with a motor and VFD (Variable Frequency Drive), our Nutsche filter ensures precise control over filtration speed and agitation.

- Mechanical Seal: A mechanical seal is provided for vacuum applications to maintain a leak-proof system.

- Hydraulic/Manual Systems: Our filters include both manual and hydraulic systems for easy movement of the agitator and discharge valve.

- PTFE Filter Support Plate: The PTFE filter support plate provides superior chemical resistance, enhancing the longevity of the filter during operation.

Specifications

- Material: Borosilicate glass

- Capacity: Custom sizes available

- Agitation Type: Mechanical

- Filtration Area: Various options to suit your needs

Benefits

Enhanced Productivity: The efficient design accelerates the separation process, allowing for quicker results and increased throughput.

User-Friendly Design: Easy to operate and maintain, our Nutsche Filter is suitable for both experienced technicians and newcomers alike.

Customizable Options: Available in various sizes and configurations to meet your specific process requirements.

Process Steps in Agitated Nutsche Filtration

The Agitated Glass Nutsche Filter operates through several important steps that enhance efficiency and quality:

- Filtration: Solid-liquid separation under vacuum, allowing the desired liquid to pass through the filter while solids are retained.

- Washing of Filter Cake: After filtration, the filter cake can be washed to remove residual solvents or impurities, ensuring the purity of the final product.

- Repeat Mixing/Washing: Additional washing or mixing processes can be applied to further purify the product.

- Convection Drying: After washing, the filter cake can undergo convection drying, removing moisture for further processing or packaging.

- Compression and Smoothing: The filter cake can be smoothed and compressed for easy handling or disposal.

- Discharge: The wet or dried filter cake is efficiently discharged from the filter for further processing.

Applications

Pharmaceutical Industry: Ideal for the filtration of active ingredients and other sensitive compounds.

Chemical Processing: Suitable for the separation of precipitates, crystals, and other solid materials.

Food and Beverage: Ensures safe and efficient filtration for various food products, complying with industry standards.

Why Choose Our Agitated Glass Nutsche Filter?

When it comes to efficient solid-liquid separation, our Nutsche Filter stands out. With advanced technology and rigorous quality standards, our product offers reliability and efficiency that sets us apart.

Investing in our Agitated Glass Nutsche Filter means choosing quality and efficiency for your solid-liquid separation processes. Whether you’re in pharmaceuticals, chemicals, or food processing, our product delivers exceptional performance tailored to your needs.