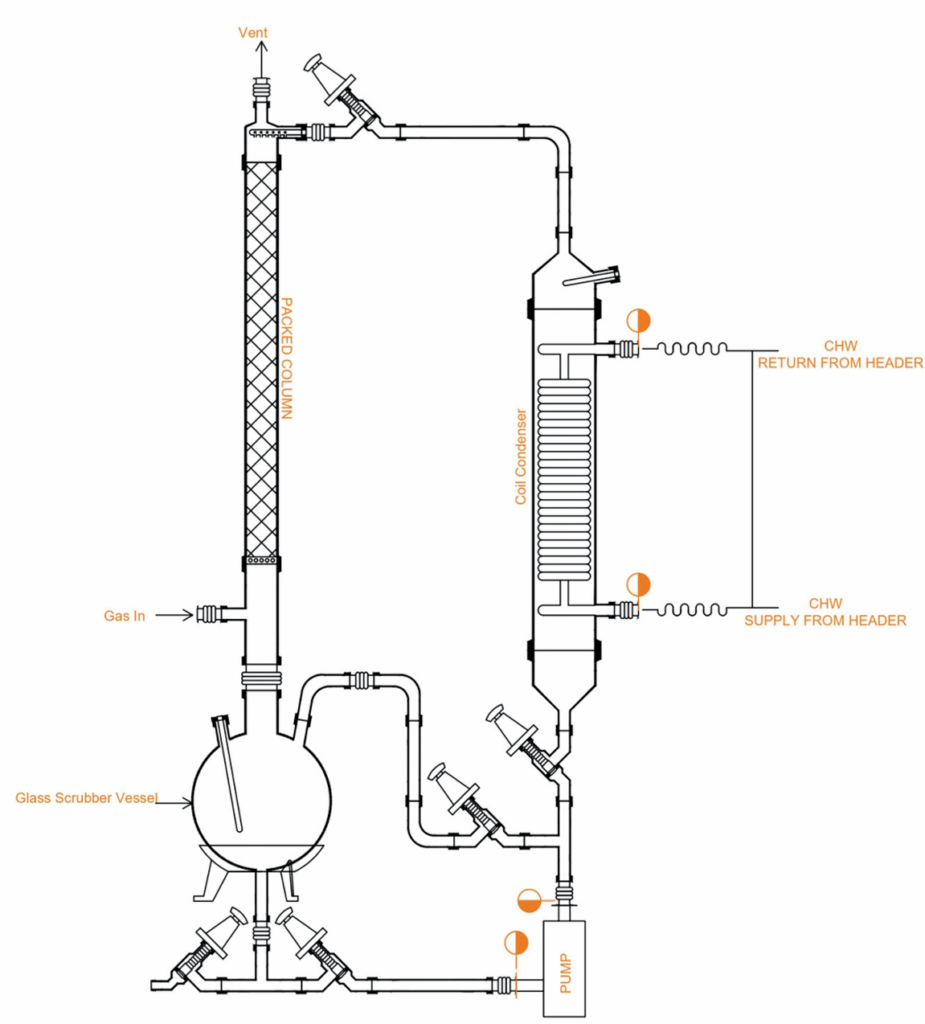

Our Cutting-edge advanced glass pilot plant gas scrubbers are engineered to manage a diverse range of gases, including HCl, Cl2, SO2, BR2, HBr, NOx, and other corrosive substances. These scrubbers employ effective media such as water, aqueous NaOH, or other suitable solvents to neutralize and treat exhaust gases efficiently and effectively.

The flow rate of the scrubbing liquid is easily adjustable using the integrated line valve, ensuring optimal performance. Additionally, the temperature of the scrubbing liquid is maintained at the desired level through a coil condenser within the liquid circuit using chilled water inside glass coils, enhancing the efficiency of the gas scrubbing process.

Our glass pilot plant scrubber is ideal for applications in pharmaceutical, chemical, refinery, and other industrial sectors. The transparent nature of glass allows for excellent process visibility, while the high corrosion resistance and minimal pressure drop enhance overall efficiency and performance.

For effective gas treatment solutions that combine durability, efficiency, and safety, choose our advanced glass pilot plant scrubbers.

Key Features

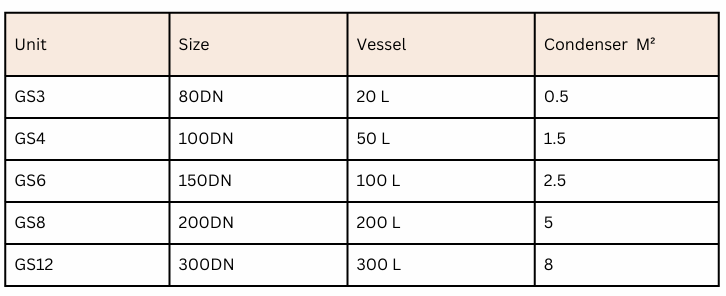

- Versatile Capacities: Available in vessel capacities from 20 liters to 500 liters.

- Customizable Dimensions: Scrubber diameters range from 80 DN to 300 DN.

- High-Performance Scrubbing: Equipped with an advanced multi-stage scrubbing process for superior contaminant removal.

- Corrosion-Resistant Design: Ensures longevity and reliability even in the most demanding environments.

- Enhanced Safety and Compliance: Meets environmental regulations and provides safe operation for various industries.

Typical Applications of Gas Scrubbers:

Off-Gas Treatment

Effective removal of harmful pollutants from industrial off-gas streams to improve air quality and comply with regulations.Exhaust Gas Neutralization

Advanced techniques for neutralizing toxic exhaust gases, ensuring safer emissions and environmental compliance.Contaminant Stripping

Efficient gas stripping methods that eliminate specific contaminants, enhancing the purity of exhaust gases.Process Scale-Up

Proven strategies for scaling up gas scrubber systems to accommodate increased production demands without loss of efficiency.Customized Process Development

Specialized process development services aimed at optimizing gas scrubber operations for diverse industrial applications.